|

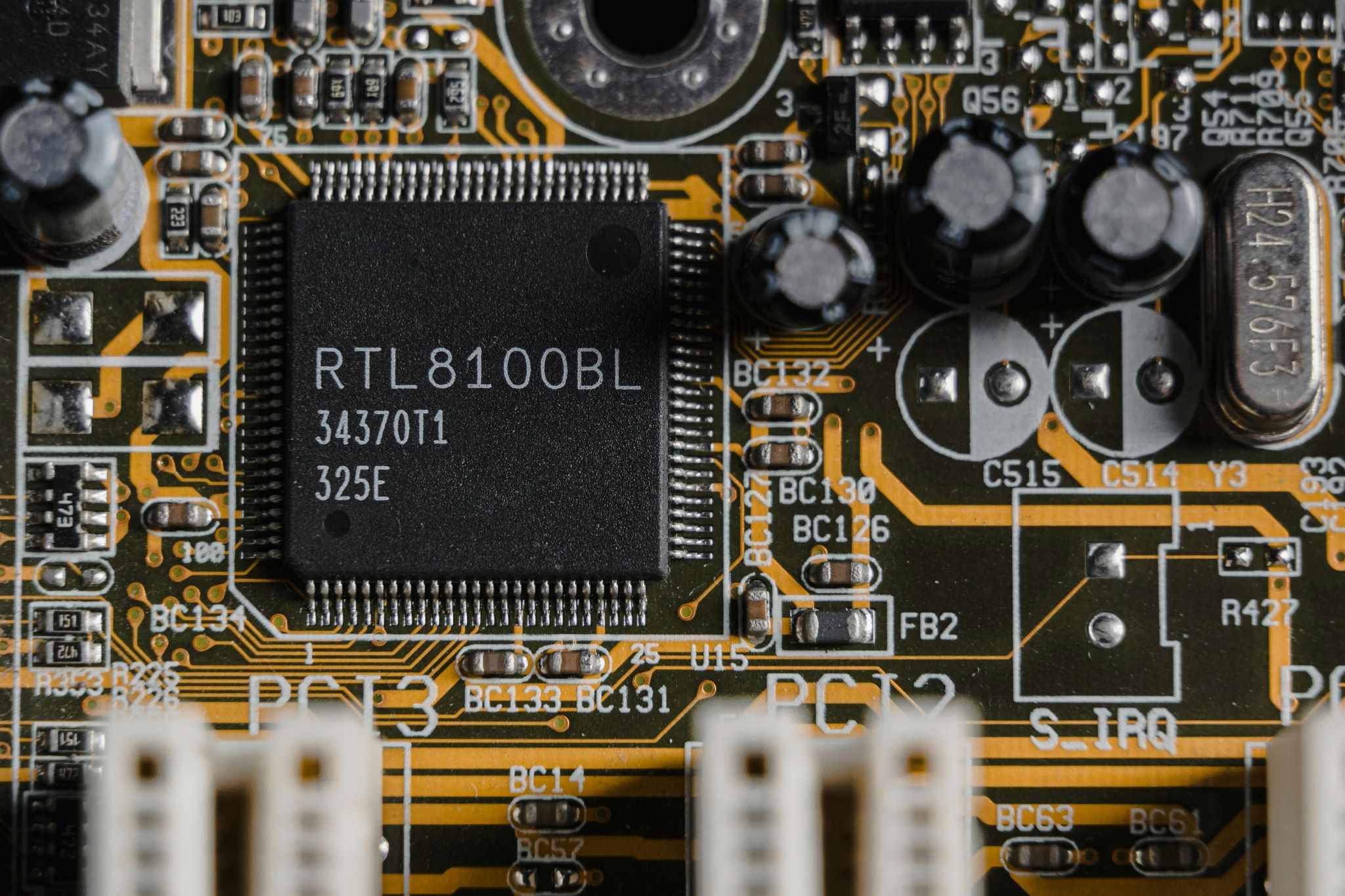

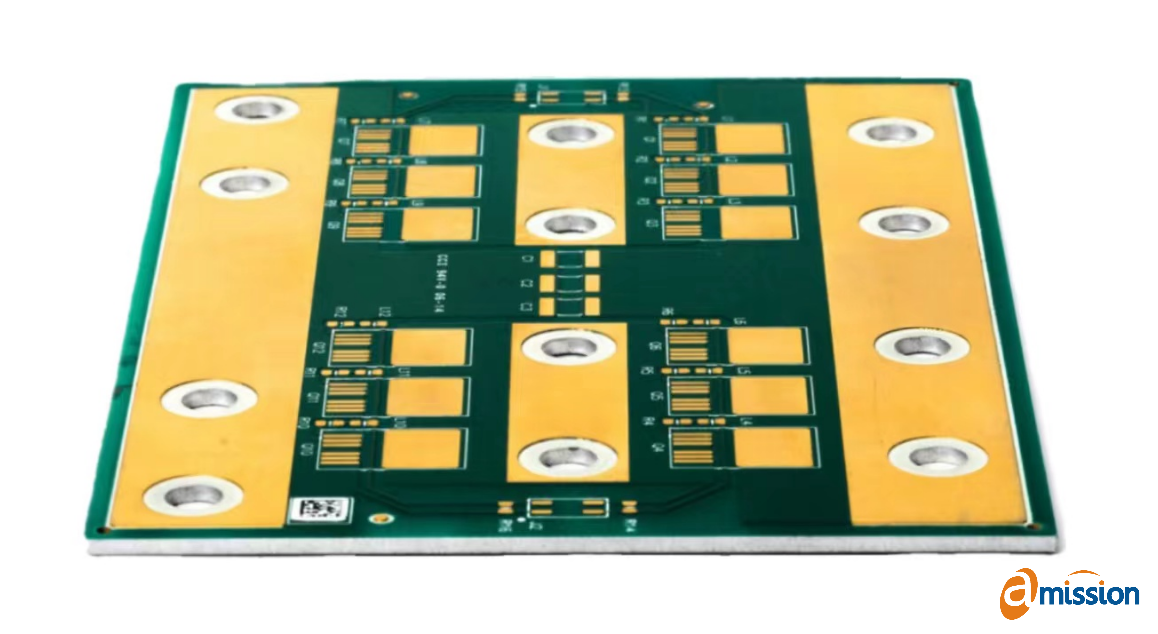

Metal Core PCB refers to a printed circuit board where the core material is metal, unlike the typical FR4 or CEM1-3. The most commonly used metals for MCPCBs are aluminum, copper, and steel alloy. Aluminum is popular due to its excellent heat transfer and dissipation properties while being relatively cost-effective. Copper provides superior performance but is more expensive. Steel, including normal and stainless steel, is more rigid but has lower thermal conductivity compared to aluminum and copper. The choice of core material depends on the specific application requirements. Typically, aluminum is the most economical option considering thermal conductivity, rigidity, and cost. Therefore, most standard Metal Core PCBs use aluminum as the base material. In our company, unless otherwise specified, the term metal core refers to aluminum, making MCPCB synonymous with Aluminum Core PCB. For Copper Core PCB, Steel Core PCB, or Stainless Steel Core PCB, special instructions must be included in the design specifications. The term "MCPCB" is often used as an abbreviation for Metal Core PCB or Metal Core Printed Circuit Board. Different terminology might be used to refer to the core or base material, leading to various names such as Metal PCB, Metal Base PCB, Metal Backed PCB, Metal Clad PCB, and Metal Core Board. MCPCBs are preferred over traditional FR4 or CEM3 PCBs for their superior heat dissipation capabilities. This is due to the presence of a thermally conductive dielectric layer. The main difference between an FR4 board and an MCPCB is this thermally conductive dielectric material, which acts as a thermal bridge between the IC components and the metal backing plate. Heat is conducted from the components through the metal core to an external heat sink. In contrast, FR4 boards trap heat if it is not dissipated by a surface heatsink. Lab tests show that a 1W LED on an MCPCB maintains a temperature close to ambient (25°C), whereas the same LED on an FR4 board heats up to 12°C above ambient. LED PCBs are usually made with an aluminum core, but steel core PCBs are also occasionally used.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Advantage of MCPCB | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| MCPCB Technics Capacity | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Please click contact us today for more information about Metal Core PCB. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||